|

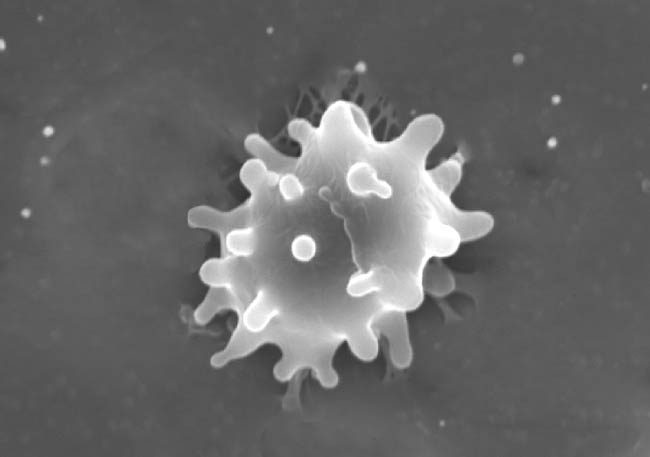

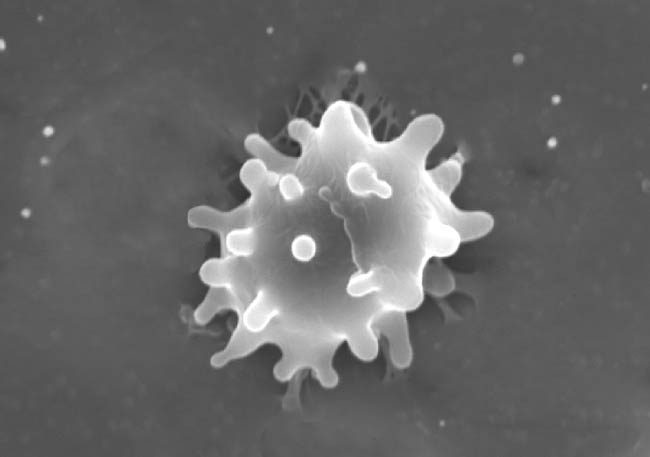

Scanning

Electron Microscope (SEM) image of a White Blood Cell

SEM stands for Scanning Electron

Microscope. The term "SEM" is used to describe a microscope used to

create high magnification, black and white images of devices with

dimensions from a few tenths of a

micron to several millimeters in diameter.

The term SEM is also used to describe the photographs taken by the

Scanning Electron Microscope. Hence, SEM refers both to the microscope,

and the photograph created by the microscope.

Traditional optical microscopes have a

very shallow depth of field. This means that images created with optical

microscopes have only a small area that is in focus. Optical microscopes

can create quality images of things that are flat, but can not create

good images of three dimensional structures because of the focus issues.

Scanning Electron Microscopes, on the other hand, have a very large

depth of field. This means that they can image complex three dimensional

structures, with all parts of the device being imaged being in focus.

This large depth of field results in stunning, sharp photographs of very

small things.

|

|

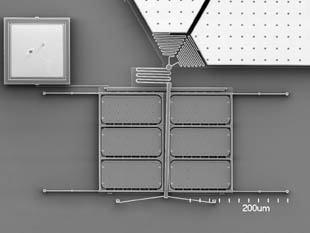

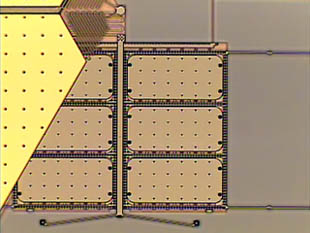

SEMs are only able to create Black and

White images. When SEM images are used in publications or books, they

are sometimes colored by a graphic artist for dramatic impact. It should

be understood, however, that the colors were added by an artist, and in

no way reflect the actual structure being depicted. Optical microscopes,

on the other hand, can create true color images. In comparing the two

photographs above, it can be seen that the SEM creates much sharper

images than what can be achieved with an optical microscope. The

two structures pictured above are

MEMS (MicroElectroMechanical System)

devices. These devices are relatively flat. The advantage of the SEM

becomes more pronounced as devices become more three dimensional.

A scanning electron microscope operates

by using a beam of electrons to image extremely small structures. The

electron beam is created by a cathode typically made of tungsten. An

electric field is used to accelerate the electron beam towards the

cathode, where the structure to be imaged is located. Coils or deflector

plates are used to scan the beam across the sample to be imaged. The

resolution that can be achieved depends on the spot size of the electron

beam. The smaller the beam, the better the resolution that can be

achieved.

In order to achieve proper creation,

control, and detection of the electron beam, the imaging must be done in

a vacuum. In addition, in order to get good contrast and resolution, the

surface of the device to be imaged must be very conductive. These

requirements of conductive surfaces, and operation in a vacuum requires

that a sample be properly prepared in order to achieve good images.

Biological samples can be damaged when placed in a vacuum, as the water

in the sample will vaporizes, which can cause the sample to explode or

dehydrate.

A typical sample preparation for

non-conductive solids, and biological samples is to coat the sample with

gold prior to imaging. A very thin coating of gold will provide the

conductivity needed, and will offer protection for fragile biological

material. The images presented on this site were all created by

first gold coating the samples.

More recently, a new type of SEM has been

developed which does not require high levels of vacuum. These

environmental SEMS allow imaging of devices which can not be coated with

gold, or prepared with other techniques. Environmental SEMS offer the

ability to image structures which previously were not compatible with

SEM imaging. The resolution and contrast of images in an environmental

SEM are typically not as good as a traditional SEM.

|